Winkelbohrspindel is an important mechanical tool used in modern machining and manufacturing industries. It helps machines drill holes at angles that straight tools cannot reach easily. Because of this special ability, many factories rely on a winkelbohrspinel to improve accuracy and save time.

Moreover, as machines become smarter and more advanced, the demand for flexible tools keeps growing. Therefore, engineers and operators often choose a winkelbohrspndel when they need precise angled drilling. This tool allows better performance without changing the entire machine setup.

Additionally, understanding how a winklbohrspindel works can help beginners and professionals alike. In this guide, you will learn what a winkelbohrsindel is, how it works, where it is used, and why it matters so much in today’s industry.

What Is a Winkelbohrspindel?

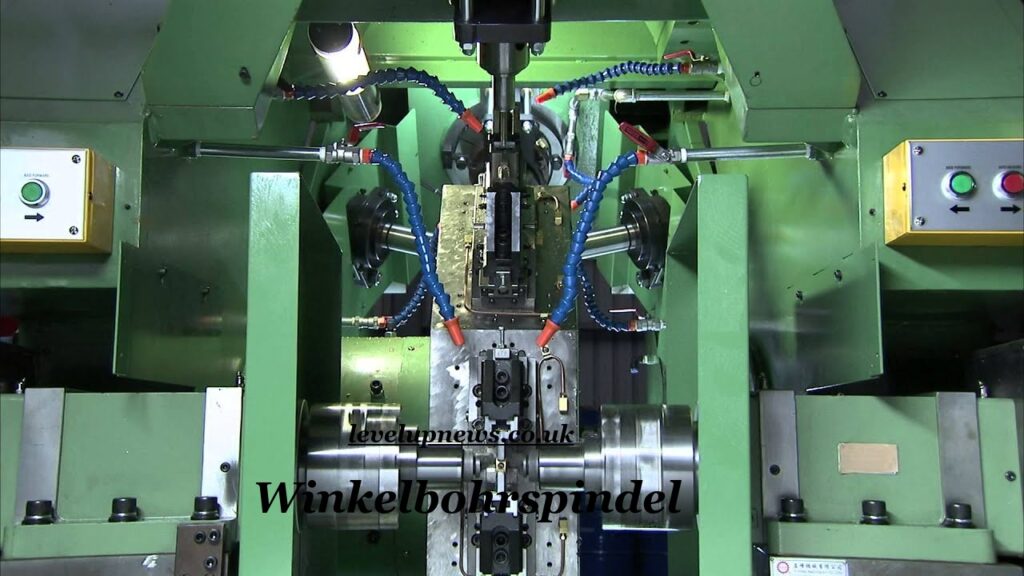

A winkelbohrpindel is a special drilling spindle designed to drill holes at an angle instead of straight down. Unlike standard spindles, it redirects motion through gears so drilling can happen sideways or at specific angles. As a result, machines gain more flexibility.

Furthermore, manufacturers often use a winkelbohrsindel in CNC machines, milling machines, and special production lines. Because of its angled design, it can reach tight spaces that normal tools cannot access. This makes it extremely useful in complex projects.

In addition, a winkelbohrsindel improves production speed. Instead of repositioning a workpiece, operators can drill from different angles using the same setup. Consequently, this saves both time and effort during manufacturing.

How Does a Winkelbohrspindel Work?

A winkelborspindel works by transferring rotational motion through internal gears. Usually, bevel gears change the direction of rotation by 90 degrees. Because of this design, the drill bit moves sideways while the motor keeps spinning normally.

Moreover, the power comes directly from the machine spindle. Once attached, the winkelbohspindel receives motion and redirects it smoothly. Therefore, the drilling process remains stable and accurate even at high speeds.

Additionally, most winkelbhrspindel units use high-quality bearings. These bearings reduce friction and heat during operation. As a result, the tool lasts longer and delivers consistent performance.

Types of Winkelbohrspindel

There are different winkelborspindel types designed for specific tasks. Some are fixed-angle spindles, while others allow adjustable angles. Because of this variety, users can choose the best option for their needs.

Furthermore, single-spindle winkelbohspindel tools handle one drill bit at a time. In contrast, multi-spindle versions drill several holes at once. Therefore, large factories often prefer multi-spindle models for mass production.

Additionally, custom winkelbohrpindel units exist for special machines. These custom designs fit unique production requirements. As a result, manufacturers gain better control over complex machining jobs.

Applications of Winkelbohrspindel in Industry

A winkelbohrspidel plays a major role in many industries. For example, the automotive industry uses it to drill angled holes in engine blocks and frames. Because precision matters here, this tool becomes essential.

Moreover, furniture and woodworking industries also rely on a winkelbohrsindel. It helps drill hidden joints and corner holes easily. Therefore, furniture makers achieve clean and strong designs.

In addition, aerospace and metal fabrication industries use winkelbohspindel tools for tight and complex parts. Since space is limited in such components, angled drilling provides a perfect solution.

Benefits of Using a Winkelbohrspindel

One major benefit of a winkelbohrspndel is improved efficiency. Since the tool drills at angles, operators do not need to reposition the workpiece. Consequently, production time reduces significantly.

Furthermore, accuracy improves when using a winkelbohspindel. The tool maintains consistent angles and depth during drilling. Because of this, the final product meets high-quality standards.

Additionally, a winkelbohspindel reduces machine wear. Instead of forcing awkward setups, the tool handles angled tasks smoothly. As a result, machines last longer and require less maintenance.

Winkelbohrspindel vs Standard Drilling Spindle

A winkelbohrpindel differs greatly from a standard drilling spindle. While a standard spindle drills straight holes, a winkelbohspindel drills at angles. Therefore, it offers more flexibility in design.

Moreover, standard spindles often require multiple setups for angled holes. In contrast, a winkelbhrspindel completes the task in one setup. Because of this, productivity increases.

Additionally, although a winkelbohrspidel may cost more initially, it saves money over time. Reduced labor, faster production, and fewer errors make it a smart investment.

Materials Used in Winkelbohrspindel Manufacturing

Manufacturers build a winkelborspindel using strong and durable materials. Hardened steel commonly forms the body and gears. Because of this, the tool handles heavy loads easily.

Furthermore, high-precision bearings support smooth rotation. These bearings reduce vibration and noise during operation. Therefore, drilling remains stable even at high speeds.

Additionally, some winkelbohrspindel models use special coatings. These coatings protect against heat and corrosion. As a result, the tool performs well in harsh environments.

Maintenance Tips for Winkelbohrspindel

Proper care keeps a winkelbohrspindel working efficiently. Regular lubrication helps reduce friction inside the gears. Therefore, operators should follow the manufacturer’s lubrication schedule.

Moreover, checking for wear and tear prevents sudden failures. Small issues can grow if ignored. Because of this, routine inspection becomes very important.

Additionally, cleaning the winkelbohrspindel after use removes dust and metal chips. As a result, the internal parts stay protected and last longer.

Choosing the Right Winkelbohrspindel

Selecting the correct winkelbohrspindel depends on several factors. First, users should consider the required drilling angle. Different projects need different angles.

Furthermore, spindle speed and torque matter greatly. A powerful winkelbohrspindel suits heavy-duty work, while lighter models fit smaller tasks. Therefore, understanding machine requirements helps in making the right choice.

Additionally, compatibility with the machine is essential. Not every winkelbohrspindel fits every machine. As a result, checking specifications before buying saves time and money.

Future of Winkelbohrspindel Technology

The future of winkelbohrspindel technology looks promising. As automation grows, demand for flexible tools continues to rise. Therefore, manufacturers keep improving spindle designs.

Moreover, smart sensors may soon become part of winkelbohrspindel systems. These sensors can monitor temperature and performance. Because of this, maintenance becomes easier and more accurate.

Additionally, lighter and more efficient materials will improve performance. As a result, future winkelbohrspindel tools will offer better speed, accuracy, and durability.

Conclusion

Winkelbohrspindel tools play a crucial role in modern machining and manufacturing. They allow angled drilling, improve efficiency, and reduce setup time. Because of these advantages, many industries rely on them daily.

Moreover, understanding how a winkelbohrspindel works helps users choose and maintain the right tool. From automotive to woodworking, its applications continue to grow. Therefore, learning about it becomes valuable for beginners and professionals alike.