The power systems productivity and reliability continues to be of major importance to various businesses. In such cases, the DIN rail power supply has proven to be one of the most important power supply units in industrial automation. Its cross-industry adaptability, reliability and ease of use in modern automation systems is a reason why DIN rails power supplies are highly sought after. This article explores the role of DIN rail power supply manufacturers and automation, emphasizes the importance of partnerships with reputable electronic component and distributor businesses, and strives to enhance faster automation systems for users.

What is a Power Supply Mounted on a Din Rail

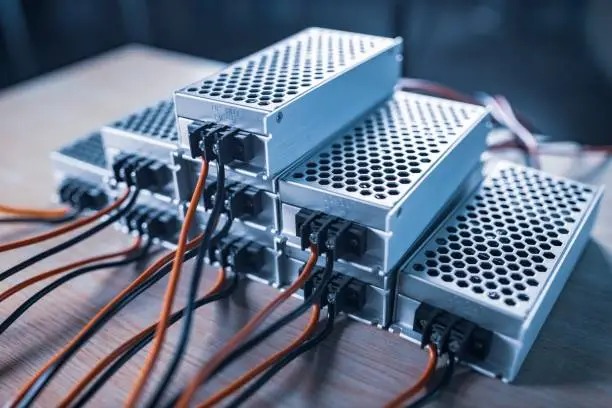

A power supply on a din rail is a specific power supply unit that is fastened on a din rail that is a type of metallic rail used to securely fasten electric equipment to control cabinets. The primary reasons for using these power supplies in industrial automation systems is their small size, ease of integration, and flexibility. A din power supply buys and converts high voltage AC to low voltage DC to ensure reliable and stable power to devices in automated systems.

The main benefit of using din rail power supplies is that businesses can easily replace and upgrade the unit with little reconfiguration. This modular flexibility is most beneficial in automated systems like control panels, equipment, and factory floors.

The Importance of DIN Rail Power Supplies for Automation Systems

All automated systems require reliable power sources, and automated systems are no exception. That is why DIN Rail power supplies are pivotal in this dingy and intricate systems:

Optimized Space: Most basic automation systems are already working in constricted spaces with very limited modules. DIN power supplies modular design saves space, which helps in keeping control modules neat and organized.

Dependability: In systems requiring constant power, dependability is a critical automation system. That is, in part, why DIN rail power supplies are dependable. Their overvoltage and overload protection safeguards ensure power is constantly maintained for critical systems.

Integration Versatility: Most industrial systems have no problems working with din rail powered supplies because they are modular in design and install with ease. This modular design also allows the individual components to be easily daisy chained to other systems, which makes them very popular in any automation configuration.

Ease of Maintenance: It is far easier to service and maintain those attributes of DIN rail power supplies because there is a standardized geometry and the mounting techniques provide a simple step-by-step procedure to swapping out power supplies.

Duties of a DIN Rail Power Supply Manufacturer

Acquisition and servicing of automation systems requires compliance and painstaking power tools which can only be sourced through a manufacturer of DIN rail power supplies. Such manufacturers deal in industrial-grade automation systems and power supplies to ensure that these entities acquire powerful, efficient, and safe power supplies specific to their operational needs.

With a DIN rail power supply manufacturer, there is certainty that the power supplies are built to last and the requisite certifications together with automation systems integration documentation will be provided.

Furthermore, the output is easier to integrate into different automation systems as many of the manufacturers can readily adjust the output to specific voltage and current ratings and/ or alter the enclosure.

Power is vital for any industry, and as such, uninterrupted power is equally important. Below is an analysis of automation benefits that have been enhanced through DIN Rail power supply. Its benefits include:

Cost-Effectiveness: Non-reliable power is expensive as its repairs and replacements occur often. Electrically efficient DIN Rail power enhances operational effectiveness, wherein remote opportunities for efficient energy conversion are maximized.

Flexibility: Automation will sometime be mandatory for any business. For long term power needs, DIN Rail Power are flexible modular options that are easy to downscale.

System Uptime: Efficient operational business automated power supply helps achieve optimal operational effectiveness. Non-volatile, uninterrupted power Beside a railway, DIN Rail Power improves system effectiveness and eliminates expensive drydocking noon costs.

Safety and Regulation Compliance: For using DIN Rail power supply, companies. Prolonged exposure to electrical hazards as well as relevant standards are neglected. Many DIN Rail suppliers assist companies in meeting essential standards of safety and help centrally supplied remote power contracts.

Collaboration with Suppliers for Efficient Integration for a DIN Rail Power Supply

\”Haste makes waste\” is a phrase that comes to mind when trying to select electronic parts suppliers for the integration of a DIN rail power supply into an automation system. These suppliers do more than simply provide the power supplies. They also include the parts such as connectors, structural fuses and circuit protection devices.

Selecting the appropriate power supplies for particular applications can be a cumbersome task for most businesses and electronic parts suppliers do assist in such matters. Whether it is the anticipated supply voltage and amperage or other requirements and specifications that are solely for a business, suppliers are capable of providing help in every component.

Operations and reliability automation systems in tandem with electronic parts suppliers define more than just enhancement of operational efficiency to most businesses.

How to Choose the Right Manufacturer for DIN Rail Power Supplies

Manufacturers for a power supply can be chosen based on a few important parameters such as:

Product Quality: Manufacturers for power supply with a good industry reputation for their reliable and durable products should be on your list. Quality certification from other industry leaders and organizations can be a good indicator of the targeted quality.

Customization Options: Different operational power needs are prevalent in every business. The ability to tune and modify power supplies to fit a business model is a far more valuable asset.

Technical Support: The manufacturers assist their clients through effective technical support. This is a very useful power supply which is being used in complex systems.

Pricing: It is crucial to view offers from different suppliers to ensure the most tactical pricing. Quality and service offered is also a great concern.

Availability: Ascertain the provider complies with the standards set by your firm. Inconsistency in the supply of required materials can trigger a halt in the production chain.

Conclusion

In the end, the power supply manufacturers are crucial to the automation systems of the operational industries. These power supplies are of critical importance in industrial environments to ensure processes are not disturbed as they are highly dependable and effective. Power supply control is essential to minimize system outages to maximize operational efficiency, and cooperation with suppliers and partners fosters optimized control of unique system power supply configurations.

The continuing advancement of automation technologies will also ensure that DIN rail power supplies remain a primary element for industrial power distribution, which offers the support and assurance needed for operational growth.